Our Divisions

Plastic Department

Being the first of the divisions founded in our company, it is also the largest in terms of investment, production capabilities and machinery park.

This division boasts 17 robotized injection moulding machines ranging from 40T to 350T being operated in three shifts when necessary with a wide range of raw materials which include:

PA6/ PA66/ PA with glass fiber 15%,20%,30%,50%/ PBT/ HDPE/ LDPE/ PVC/ PP/ PP with talc/ ABS/ PS/ ALTUglass/ Resina Acetalice. In help to the wide range of products manufactured in the plastic department come also the numerous moulds which count to 120 individual moulds of diferent sizes, configurations and specification. It has been achieved a large production quantity capability with the highest quality norms

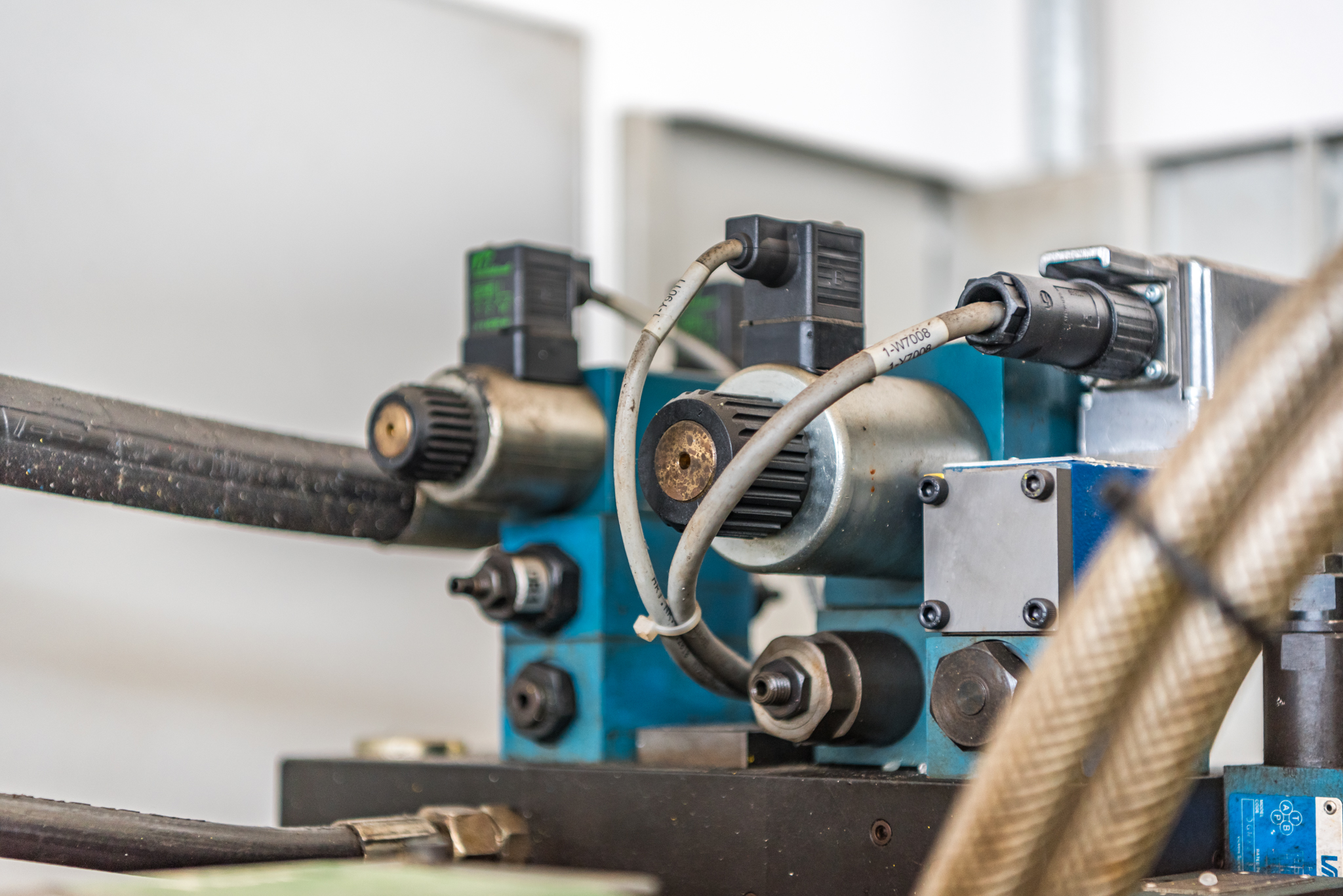

Metallic Department

•Within this division we count 6 eccentric metal presses ranging from 15T to up to 70T including motorized reel, pneumatic and electric eeders, blank holders, photocells for mould protection and 160T hydraulic press.

By deforming, bending, bowing, cutting and many other operations to metalic components, this divisions comes to aid for necessary metalic products in the assembly phase of our finished products.

Textile Department

By far some of the most interesting machines in our company are found in the textile divisions combining machines that require very high speed and precision of multiple moving and very delicate parts. These machines inclide:

- 6-band machines that produces rope from 10mm up to 30mm

- 8-band machine for ropes from 10mm up to 30 mm

- 7×2-band weaving machine for cords from 1mm up to 10mm

- 2 hot cutting machinery, programmable for length up measure

- 4 automatic programmable winding machines

Sewing Department

A fairly new organised department but nonetheless well invested and equipped is the sewing department which bosasts:

- Automated cutting bench for cutting fabric

- 8xtripple transport Dürkopp-Adler sewing machines for heavy fabrics

- 10 linear JUKI stitching machines

- Welding machine bench 1.5m x 6m sliding bench

- Welding mchine HF-15kW

- A 16x3m automatic cutting table equipped with a rotating cutting blade

- 2x die cutting machine, bench 2m x 0.6m

Engineering Department

• To achieve the best engineering solution, DELD collaborates with our partners at our Technical Office in Tirana where we are able to design and draw plastic parts using software such as CATIA V5 and NX.

• The newmoulding division which should be fully operational by mid- end of 2024 can achieve the preparation of about 3 moulds per month, in a maximum of 500 by 500cm in dimensions and for both metal presses and injection moulding machines